Extraordinary tableware for less

Save more when you spend more.

T&Cs apply.

Save £30 on our top picks with code SAVE30

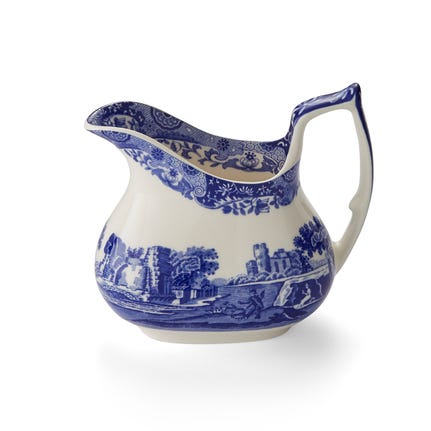

Get ready for National Tea Day

Save up to £30 on your favourite teaware with Spend & Save.

Shop TeawareSpend & Save

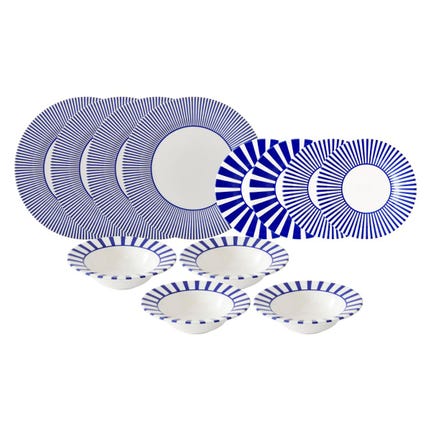

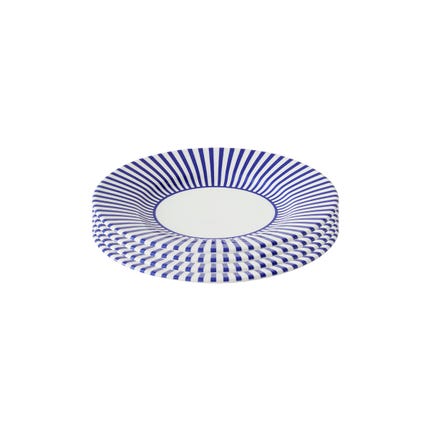

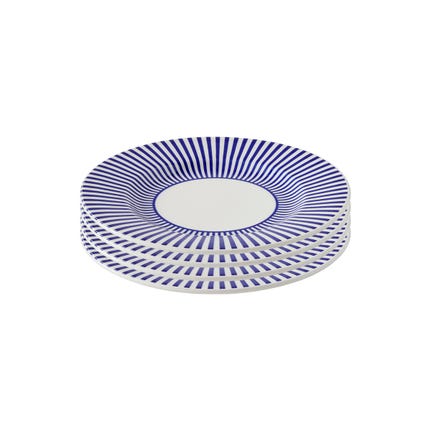

Blue Italian & Brocato

Mix & match Blue Italian & Brocato, and save more with Spend & Save.

Shop NowShop NowThe Edit

front